To assure the quality demanded by customers, we, at![]() , have been making a generous investment in testing equipment. To name a few, we have a X-ray non-destructive inspection system for seeing through hidden defects inside the castings; a Blister inspection equipment for checking if castings can stand the solution heat treatment such as T6; a Supersonic flaw detector for finding faults even the X-ray device overlooks; a Rockwell hardness tester for checking wear-resistance; an Optical stereomicroscope for checking microfabricated surface. Furthermore, to assure intended quality upon the completion of product development, we make various analysis beforehand such as CAD (2D, 3D) analysis, Fluidity and solidification analysis and FEM analysis. These contribute to saving tremendous amount of man-hours in developing new product.

, have been making a generous investment in testing equipment. To name a few, we have a X-ray non-destructive inspection system for seeing through hidden defects inside the castings; a Blister inspection equipment for checking if castings can stand the solution heat treatment such as T6; a Supersonic flaw detector for finding faults even the X-ray device overlooks; a Rockwell hardness tester for checking wear-resistance; an Optical stereomicroscope for checking microfabricated surface. Furthermore, to assure intended quality upon the completion of product development, we make various analysis beforehand such as CAD (2D, 3D) analysis, Fluidity and solidification analysis and FEM analysis. These contribute to saving tremendous amount of man-hours in developing new product.

See-through image with X-ray device |

Microfocus X-ray Microscope |

Blister inspection equipment |

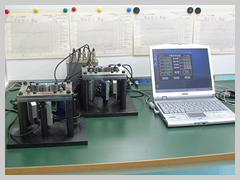

Supersonic flaw detector |

Rockwell hardness tester |

Optical stereomicroscope |

CAD (2D, 3D) |

Fluidity and solidification analyzer |

Linear gauge Flatness tester |

Copyright KOBAC Engineering Co,. Ltd. All Rights Reserved.